Overview

Off-shore wind is a technologically reliable and financially cost-effective energy source that has become an integral part of the world response to combat climate change. As the demand for off-shore wind increases, technological advances will continue to utilize high voltage inter-array cables. To reliably mitigate risks related to the performance of HV array cables, we now offer proven off-shore commissioning testing for HV cable systems.

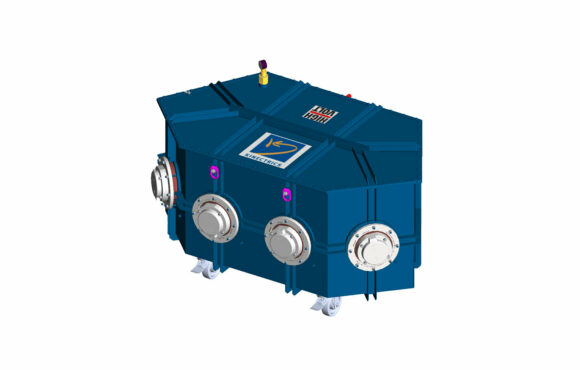

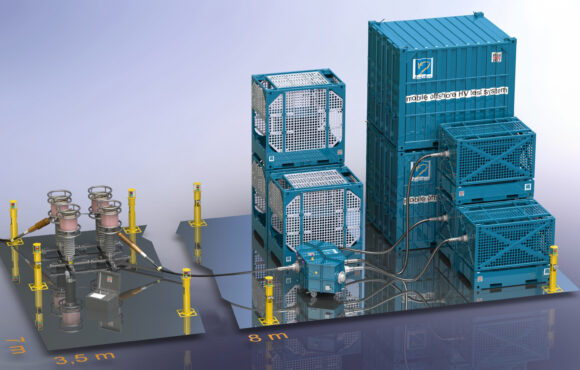

Our light weight, modular Resonant Test Sets (RTS), in conjunction with proven field-testing partial discharge monitoring technology, can test entire strings rated 66 kV (tested at 72 kV) up to 40 km of length end-to-end in their final operating configuration. The combination of high-potential (high-pot) and partial discharge (PD) testing allows for the detection of installation-related life-limiting defects prior to energization, thereby reducing the risk of in-service failures.

Why Us?

-

Complete Off-Shore Cable Testing

We own and operate eight high powered resonant test sets and have tested export cable system from on-shore substations to off-shore platforms. Therefore, we are well equipped to provide full test solutions for both offshore inter-array cable commissioning testing, as well as export cable commissioning testing.

-

Full Cable Lifecycle Experience

As an independent service provider, we support type testing of HV cable systems, conduct forensics and in-service failures of MV & HV cable system components, and are backed by full-fledged laboratory capabilities. Our cradle to grave experience with HV cable testing allows us to provide unique insights into long-term performance of HV cable systems based on proven test results.

-

Extensive MV, HV & EHV Cable History

We are formerly part of Ontario Hydro Research Division before being privatized, have collectively been testing MV, HV and EHV cable systems in the field since the mid-1970s. Many of the technological approaches used today stem from the research we conducted in collaboration with other entities, such as EPRI.

Technical Abilities

Off-Shore Commissioning Testing for HV Cable Systems

- Each module of the test system is enclosed in a DNV-certified 10-foot container weighing less than 3.7 metric tons.

- The modular design allows us to ship the minimum number of resonant test reactors required to site, helping to reduce the space constraints on the off-shore substation.

- The main part of the system is placed on the top or roof deck connecting the inter-array cable string under test to the Resonant Test Set (RTS).

- The system can typically be erected in less than two days allowing for one, two or three conductors of a string to be tested in a 10-hour shift.

- The commissioning tests can be performed during night shifts to ease work planning complications associated with other ongoing work on off-shore substations (OSS).

Additional Tests

- Tanδ (tan delta) tests in conjunction with commissioning testing

- Dielectric spectroscopy tests

- Cable line resonance analysis (LIRA)

- Optical time domain reflectometry (OTDR)

- Time domain reflectometry (TDR)

Our Proven Experience

Quality Assurance & Technical Standards

- CIGRE TB 728

- Guidelines for On-site Partial Discharge Assessment of HV and EHV Cable Systems

- CIGRE TB 841

- For AC and DC Cable Systems with New Technologies

- IEC 60840

- Power cables with extruded insulation and their accessories for rated voltages above 30 kV (U<sub>m</sub>= 36 kV) up to 150 kV (U<sub>m</sub> = 170 kV) - Test methods and requirements

- IEC 62067

- Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) - Test methods and requirements

- IEC 63026

- Requirements for Submarine Power Cables with Extruded Insulation and Their Accessories