Degraded Nuclear Piping Overview

Nuclear pipes that have been in place since plant construction and are nearing their expected design life require inspection as they have the potential to be degraded (i.e., wall thinning or display evidence of a leak). Depending on the situation, having a repair plan in place is essential.

One reliable option is to pursue a non-metallic on-pipe repair solution that avoids moving, re-routing, or abandoning piping and instead uses a polymer resin to fully repair it, so that it can support the intended design load.

With decades of nuclear experience, our experts have developed reliable and innovative composite repair solutions. This includes the design and installation of Carbon Fiber Reinforced Polymers (CFRP) that can be used for full structural repairs, avoiding the need for costly pipe replacements.

Why Our Degraded Nuclear Piping Services?

-

Industry Experts

A world-class team comprised of composite and piping subject-matter experts. We collaborate to provide optimal, customized solutions for our customers.

-

Decades of Experience

Our commitment to safety and quality has been proven through decades of experience working with nuclear power plants and utilities to provide the best-in-class solutions.

-

Full Structural Replacement

Uniquely designed to effectively replace existing pipes in nuclear plants, without having to remove them, which delivers significant cost savings.

-

Custom CFRP Repair Solutions

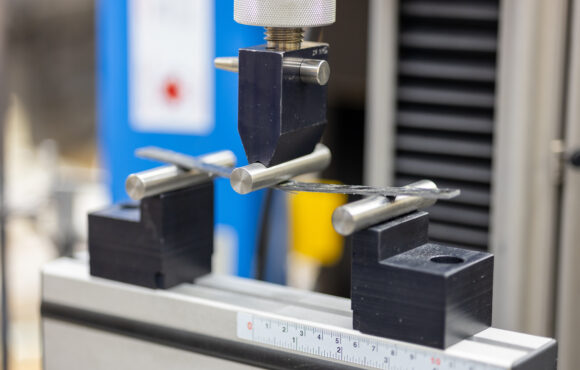

Our extensive test program includes long term and elevated temperature tests. Our CFRP product is verified according to ASME Code Case N-871 and PCC-2 under our certified nuclear QA program.

Our Degraded Nuclear Piping Technical Abilities

Full-Service Support

Our team delivers the full suite of services needed to assess, design, develop, implement & license a non-metallic repair solution, all within your nuclear plant’s engineering change control/modification processes.

- Design Engineering

- Nuclear Accredited Testing Program

- Licensing Support

- Installation of Non-Metallic Repair Solutions

- In-Service Inspections

Non-Metallic Repair Solutions

Non-metallic solutions are often sought after because you can do them in-situ (on-pipe repairs) versus traditional metallic methods which require replacing the pipes.

Whether it's buried piping, or any other aging pipes in your existing nuclear plant, our team is here to help offer an in-situ repair solution.

We offer a variety of customized solutions to meet our clients' needs and achieve up to 50 years of service life, such as:

Carbon Fiber Reinforced Polymer (CFRP)

- Lab-tested by in-house subject-matter experts.

- Ambient cured – Cost effective, more achievable than elevated temperature-driven solutions.

- Offers internal or external repair solutions.

- Highest strength to thickness ratio.

Other Solutions

- Cured-in-Place Pipe (CIPP) – Cured in place resin suitable for small to medium diameter pipes with straight runs.

- Sprayed-In-Place Pipe (SIPP) – Sprayed in place resin installed by robotic or manual spray rigs for internal repair of pipes.

Exceptional Partnerships

We developed our CFRP repair solutions in partnership with A&G Industrial Services. A&G has over two decades of experience installing composite repair solutions.

Today, A&G continues to pioneer in the field of applied technologies with the highest certainty of outcome for use in a broad spectrum of industrial applications.

Our Proven Experience

Quality Assurance & Technical Standards

- ASME PCC-2 (2018)

- Repair of Pressure Equipment and Piping

- ASME Section XI Code Case N-871 (In Progress)

- Repair of Class 2 and 3 Piping Using Carbon Fiber Reinforced Polymer Composite