Fuel Channel Inspection Overview

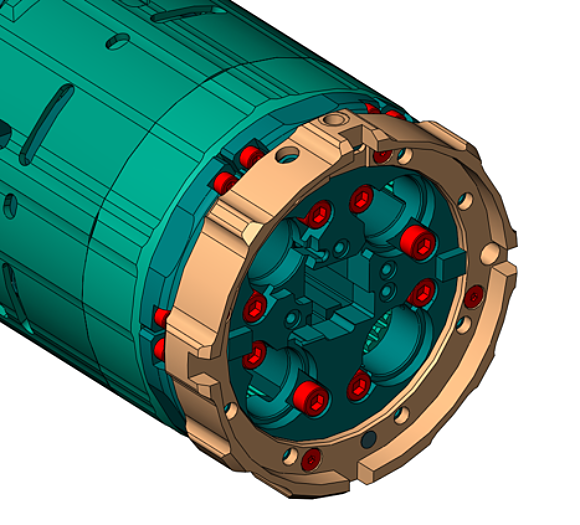

The fuel channel of a CANDU reactor comprises two concentric tubes, a Calandria Tube (CT), and a Pressure Tube (PT), one inside the other. Each fuel channel is supported by the end shield lattice tubes through sliding bearings and by the annular spacers between the two tubes.

The annular spacers can move, and this could lead to contact between the pressure tube and the calandria tube, potentially leading to a pressure tube failure. The spacing is confirmed during inspections and adjustments are made to ensure safe reliable operation.

Additionally, hydrogen can build up within the zirconium alloys used in the pressure tubes and this can lead to changes in the alloy’s physical properties. Operators must keep a close eye on this build-up to ensure the safety of their asset and to satisfy the requirements of their regulators for continuous fit for service operation.

Our fuel channel inspection services are based around our Circumferential Wet Scrape Tool (CWEST*). We also support the legacy tool sets owned and operated by you including:

- The Spacer Location And Repositioning tool (SLAR)

- The Advanced Non-Destructive Examination tool (ANDE)

- The Channel Inspection and Gauging Application for Reactors tool (CIGAR)

- The Terminal Solid Solubility tool (TSS)

Our work on fuel channels is part of our comprehensive range of outage services that also include steam generator and feeder inspections, fuel integrity monitoring, and other bespoke inspections and maintenance activities.

*CWEST not available for sale outside of Canada until after November 30, 2027.

Why Our Fuel Channel Inspection Services?

-

Familiarity with Tool Set

We are the designer and original equipment manufacturer of many fuel channel tools and are well acquainted with the way they operate having deployed them on many campaigns. This familiarity allows us to work quickly, safely, and efficiently to produce results in which you and your regulator can be confident.

-

Rapid Response Capability

Our permanently employed Power Workers Union and Society of Energy Professionals staff, allow us to mobilize quickly to deal with emergent issues. We identify the problem and establish and implement solutions, all in one smooth exercise, allowing you to focus on your other critical outage activities.

-

Outage Focused Approach

A NASCAR-style front-of-house (Service Center) and Pit-Crew approach is used for our outage work. A front-of-house team handles the customer interface, organization, and documentation enabling the pit crew to focus on the equipment they service and maintain.

-

Safety First

Safety is a core value for us. Our work is planned with safety in mind using all our specialists including those in radiation protection, conventional safety, and human performance. You can be sure we will work with you to deliver event-free outcomes.

Our Fuel Channel Inspection Technical Abilities

Circumferential Wet Scrape Tool (CWEST*) Pressure Tube Scrape Sampling

We provide full outage site support services for CWEST*. This starts with staff training at the CWEST* Maintenance and Test Facility (CMTF) where our technicians develop their experience in operating the tool both on the operator panel and hands-on with the tool. We also maintain and update the field execution procedures for both Bruce Power and Ontario Power Generation.

OPEX from previous campaigns is reviewed and improvements are implemented so that a clean set of procedures is available for every outage. Additionally, vetting of the procedures and qualification of staff is captured through pre-outage dress rehearsals performed on our retrieval cart mock-up. This mock-up includes capabilities for headset communication and full plastic suit training for both new and experienced staff. All of our staff are trained in field deployment human performance tools.

Depending on your needs, our service may include a full crew to complete all the scope of the outage or may be secondary support to your crew. A typical CWEST* outage crew includes an oversight manager, subject matter experts, quality control inspectors, technicians, and a team lead. This crew allows for successful CWEST* campaigns with a combination of technical experts performing both vault and tool operation activities while subject matter experts provide oversight and lead troubleshooting activities.

We can stage and set up the equipment in the vault including making the cable and tool cable connections, powering up the systems, and carrying out all the functional tests. This setup is followed by a regular cycle of on-channel scrape operations, scrape sample retrieval, and cutter inspection and replacement. Finally, the equipment is demobilized before support is provided for the retrieval flask shipping that enables analysis.

*CWEST not available for sale outside of Canada until after November 30, 2027.

Staff Support

We can provide technician support to augment your staff for any fuel channel NDE inspection tooling deployment including for advanced NDE (ANDE), channel inspection and gauging apparatus for reactors (CIGAR), Replica, and spacer location and repositioning (SLAR).

Our technicians are trained and qualified to operate these tools at your facilities. They can be part of your crew, seamlessly integrating into your field team, and providing flexibility to support various shift schedules. Our technicians also have CGSB qualifications for Eddy Current (ET) and Ultrasonic Testing (UT) should it be needed.

Our Proven Experience

Quality Assurance & Technical Standards

- CAN/CGSB-48.9712 (2019)

- NRCan National Non-Destructive Certifcation Body

- CSA N285 Series

- General Requirements for Pressure-retaining Systems, Components, and Supports in CANDU Nuclear Power Plants

Key Clients

Projects

BRIMS Maintenance & Execution Program