Expert Materials Consultation Overview

Material selection is the act of choosing the material best suited to achieve the requirements of a given application. Many different factors go into determining the selection requirements, such as its mechanical, chemical, physical, or electrical properties, and the potential associated cost. Consideration must also be given to the potential for degradation caused by heat, fatigue, corrosion, radiation damage, and structural or chemical change.

As a result, the appropriate selection of materials requires a wide range of knowledge from experts such as materials scientists, design engineers, production engineers, and procurement agents. Operational experience is also very helpful.

When in service, materials may fail or degrade, and a forensic investigation could be needed to establish what processes have given rise to the problem. These forensic investigations can be complex as they need to consider all the potential degradation mechanisms and often have to be supported with inspection and testing.

Materials whether metals, ceramics, polymers, rubbers, composites, or concrete lie at the core of our work. Our experts in materials science come from a variety of specialties and offer a depth of knowledge so that they can solve your toughest materials problems.

With state-of-the-art materials laboratories, and access to experts across the company, we can work with you to advise you on your optimum material selection.

Why Our Expert Materials Consultation?

-

State-of-the-Art Laboratory Equipment

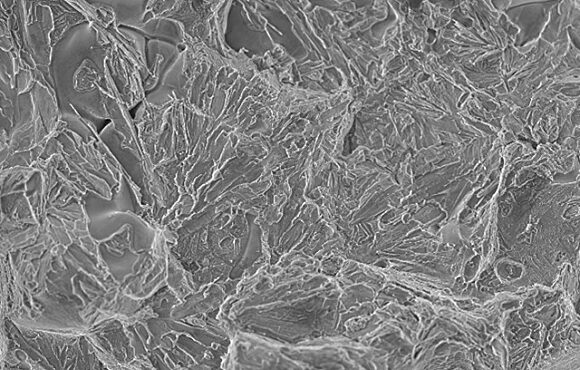

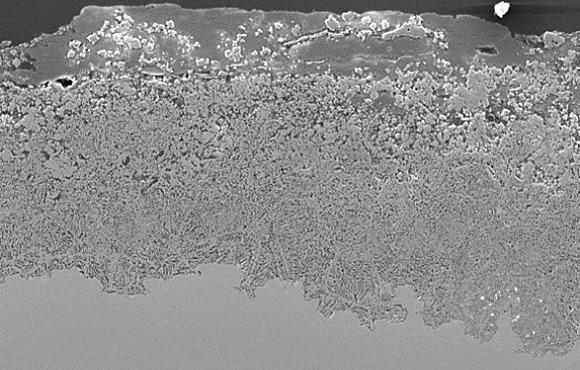

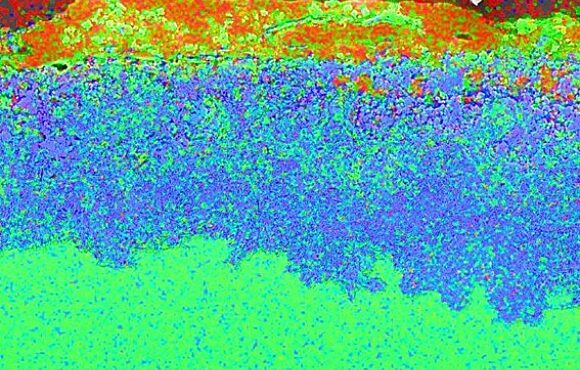

Our comprehensive materials investigation capabilities are supported by state-of-the-art materials testing labs, irradiated materials testing labs, corrosion test equipment, and specialized equipment such as a scanning electron microscope with electron backscatter diffraction and energy dispersive X-ray analysis.

-

Experts in each Class of Material

We have subject matter experts for each class of materials including metals (notably zirconium alloys), polymers, ceramics, concretes, glasses, and composites used for their structural, electrical, magnetic, or atomic properties ensuring we can answer whatever materials questions that you need answered.

-

Research Expertise and Practical Expertise

By combining research and practical experience from our materials scientists, design and procurement engineers, technicians, and research scientists we can relate the fundamentals of materials performance to the application and provide well-rounded advice.

-

Responsive and Flexible

With all the expertise and comprehensive testing capabilities in-house, we can quickly mobilize the right materials team needed to resolve any challenges enabling us to provide a swift response to any of your materials questions.

Our Expert Materials Consultation Technical Abilities

Metallurgy

We have journey-person and expert-level metallurgists who provide materials consultation in forensics and failure analysis, materials selection, and component life management and assessment. Our experienced metallurgists have practical experience working with ASTM, ASME BPVC, CSA, AWS, NACE, and API.

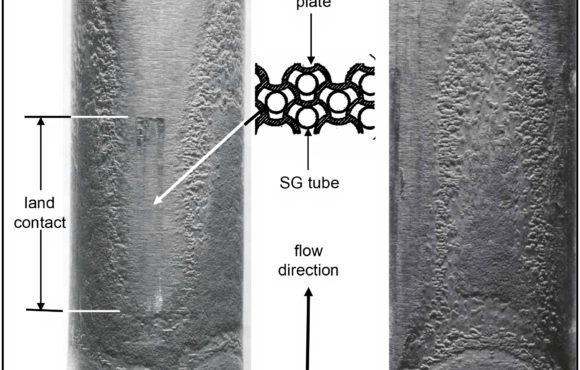

Corrosion

Our corrosion group has decades of experience in fitness-for-service examinations of ex-service feeder tubes and steam generator components in support of CANDU major components periodic inspection and lifecycle management programs. We design and execute corrosion testing programs to determine end-of-life conditions and to test new materials and technologies.

The corrosion team also has several years of experience conducting buried piping inspections and cathodic protection assessments at nuclear facilities. Our corrosion experts are qualified to NACE CIP Level 3 and provide corrosion engineering consulting on:

- Buried piping inspection programs and execution,

- Corrosion control and asset integrity management (AIM) of critical components

- Cathodic protection design

- Electrochemistry in high-temperature high pressure aqueous systems

Polymers and Other Non-metallic Materials

Our industry-leading polymer experts provide specialized services in the condition assessment, failure analysis, material characterization, and testing of polymer-based materials, including elastomers, composites (such as fiberglass and carbon fiber), and solid dielectrics, with a focus on the effects of environmental, thermal and radiation aging. We also provide non-electric testing of medium voltage and high voltage cables to international standards such as IEC, CSA, IEEE, UL etc.

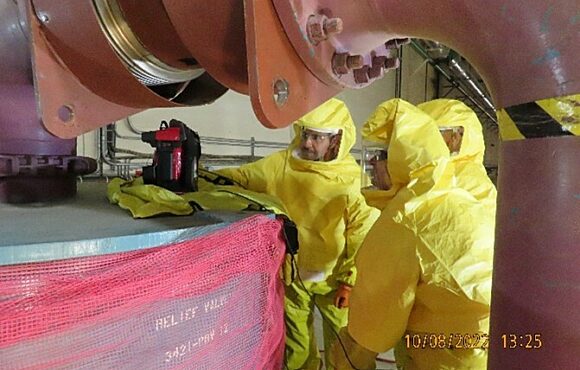

These services extend into expert consultation for Environmental Qualification and Commercial Grade Dedication of nonmetallic components. Our team is often deployed in the field for the inspection of composite and sealing materials during outages including the fiber-reinforced-polymer inspection of the headers in the vacuum building.

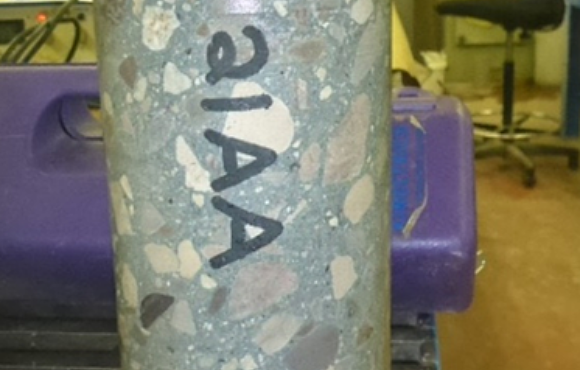

Concrete Material Expertise

We are nuclear-quality concrete experts, providing advice and services to all Canadian nuclear facilities. Our team is the primary supplier of R&D and material qualification for concrete repair materials to the CANDU industry. We provide rehabilitation and repair services, from inspection through advice, to field oversight and repair. Our expertise includes concrete condition assessment, coating and repair material qualification, repair specification, field repair, concrete, and structural analysis.

Advanced Materials and Advanced Manufacturing

Our materials experts provide specialized material consulting for harsh environments and unique applications such as those required for Small Modular Reactor and Fusion applications. We can work with you to qualify your material or develop new materials and test programs for you to satisfy your unique design and operational requirements. We are presently working on the qualification and testing of materials produced by advanced manufacturing techniques which if approved could radically change the way some challenging nuclear components are produced.

Our Proven Experience

Quality Assurance & Technical Standards

- CSA N285.4 (2019)

- Periodic inspection of CANDU nuclear power plant components

- CSA N285.8 (2015)

- Technical requirements for in-service evaluation of zirconium alloy pressure tubes in CANDU reactors

- ISO 9001:2015 (2015)

- Quality management systems