High Current Testing Overview

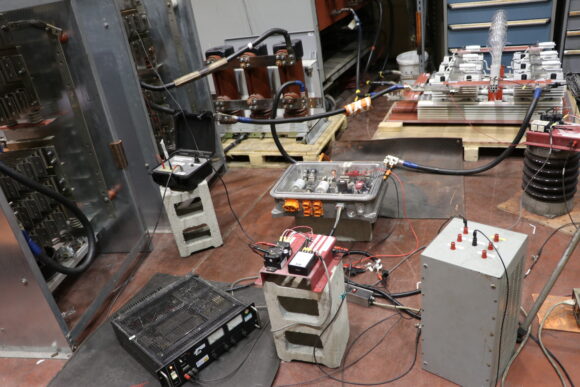

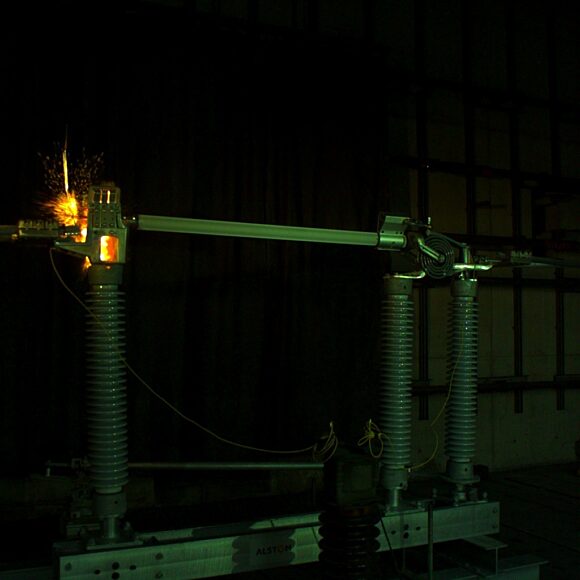

In modern transmission and distribution power systems, reliability, power quality, and public safety are key factors in system design and planning. High current laboratory tests are performed to determine the design effectiveness, robustness and safety margin of key electrical equipment.

Our High Current (HC) lab facility and our qualified and experienced technical team ensure your equipment components and products meet or exceed industry standards and deliver maximum performance. We offer high quality and reliable testing using state-of-the-art equipment and calibrated instruments. From transmission class disconnect switches to small connectors, we offer a full range of independent, confidential services to provide quality fault current tests for certification and for product development. We also do short circuit testing of transmission and distribution equipment and qualification of EV chargers and components.

Our high current lab can be trusted to provide independent third-party testing services to utilities, manufacturers, certification bodies, engineering firms, and end users.

Why Our High Current Testing

-

No Test Current Overshoot

Our high-current transformers are fed from the grid because the constant source impedance gives rise to a short-circuit current that is stiff, stable, and reliable. This avoids the problems with different transient, sub-transient, and steady-state reactance variations found in generators and eliminates the test current overshoot for the first few cycles, which is inevitable when using generators.

-

Proven Expertise

For over four decades, we have been at the forefront of testing transmission and distribution equipment. We have served over 38 countries and tested for over 500 manufacturers and utilities. We have delivered over 4,000 projects to qualify high-quality products and instill confidence in system reliability. This adds up to over 15,000 pieces of equipment tested.

-

Enabling Electric Vehicle Deployment

We offer testing services for both the components on the electric vehicle itself and in the charging stations and chargers ensuring that electric vehicles can be deployed safely and reliably.

-

Ensuring the Safety of Electrical Workers

The decades of experience that lie behind our arc flash testing services for personal protective equipment will give you and your workers confidence that proper protections are in place.

High Current Testing Technical Abilities

High Current Tests on Transmission and Distribution and Industrial Equipment

We conduct single phase and three phase short circuit tests, continuous current tests, internal arcing fault current tests, and endurance tests on transmission, distribution, and industrial equipment.

Electric Vehicle (EV) Components & Chargers Testing

The automotive industry has been experiencing an unprecedented transition which is leading to a complete revision of the mobility concept. The process of electrification is bringing about change in the market that requires extensive and accurate testing to sure components safely and reliably operate as designed.

We offer short circuit and continuous current tests, endurance tests, fault current make and interrupt tests, and overload current switching tests on EV components such as contactors, fuses, and power distribution units.

Testing Electric Vehicle (EV) Chargers

EV charging stations and chargers need to be tested to ensure they are working correctly and safely. Any issue that may arise from a faulty charger could result in costly damage to the fragile electronics and batteries that power electric vehicles.

We offer a full range of qualification tests on AC and DC Fast Chargers used for electric cars and buses including electrical, mechanical, environmental, and power quality tests and measurements.

Arc Flash Testing of Safety PPE

Our high current lab has decades of experience testing arc flash Personal Protective Equipment (PPE). When it comes to the vetting of your PPE products, we offer reliable results and peace of mind with our years of testing expertise and industry knowledge. As pioneers in the science of testing, we continue to innovate and lead the industry in the delivery of top quality, accurate Arc Ratings to ensure the safety of electrical workers around the world.

We are the world leader in arc flash testing of textile materials, eye and face protective products, garments, hoods, gloves, blankets, fall protection, and other PPE products.

High Current Lab at a Glance

- 200 MVA short circuit capacity

- Directly fed from grid, providing a constant current source

- Custom made robust short circuit transformers

- 16 m (L) x 6 m (W) x 7 m (H) enclosed concrete test cell to suspend overhead conductors for short circuit testing up to 20,000 lbs tension.

- Six-pulse high power rectifiers; 2500 Vdc, 12000 A rated current, 67 kA momentary current

- A draft free heat rise test room equipped with temperature control system

Testing Capacity

- 60hz Continuous, Single Phase 75 V

- Maximum continuous current: 16 kA

- 60hz Continuous, Single Phase 150 V to 2.4 kV

- Maximum continuous current: 4 kA

- 60hz Continuous, Three Phase 25 V

- Maximum continuous current: 8 kA

- 60hz Continuous, Three Phase 300 V to 1.2 kV

- Maximum continuous current: 4 kA

- 60hz Momentary, Single Phase 50 V to 3k V

- Maximum short-term current: 80 kArms

- Maximum momentary peak current: 200 kA

- 60hz Momentary, Single Phase 3 kV to 20 kV

- Maximum short-term current: 12 kArms

- Maximum momentary peak current: 30 kA

- 60hz Momentary, Three Phase 300 V to 1.5 kV

- Maximum short-term current: 50 kArms

- Maximum momentary peak current: 120 kA

- DC up to 2 kVdc

- Maximum short-term current: 50 kArms

Transmission & Distribution Equipment Testing

- Pad-Mounted and Pole-Mounted Distribution Transformers

- Short circuit current withstand test

- Internal arcing fault current withstand test

- SFRA

- DGA

- DC resistance

- Load loss and no-load loss

- Dielectric tests

- Disconnect and Ground Switches

- Short time current withstand tests

- Momentary peak current withstand tests

- Heat rise tests

- Dielectric tests

- Switchgears

- Continuous current test

- Short time withstand tests

- Fault current interrupt tests

- Short circuit tests on CTs

- Short circuit tests on bus ducts

- Power arc tests on distribution insulators

- Fuse testing

- Short circuit tests on overhead line conductors, connectors, and spacers

Testing EV Components

- DC Contactors

- Short circuit withstand test

- Current carry capability tests

- Fault current making tests

- Fault current interrupting tests

- Overload current switching tests

- Mechanical and electrical endurance tests

- Fault current interrupt capability tests on fuses and Pyro fuses

- Fault current tests on EV power distribution units

Testing EV Chargers

- Electrical Tests

- Enclosure leakage current

- Temperature test

- Ground fault detection

- Capacitor discharge

- Short circuit

- Dielectric

- Dew point test in humidity chamber

- Endurance test with load on plugs

- Forced ventilation

- Mechanical Tests

- Impact test on enclosure

- Vehicle drive over cable

- Pull and push back strain relief

- Impact on glass cover

- No-load endurance tests on plugs

- Polarization integrity

- Environmental Tests

- Water exposure

- UV exposure

- Chemical exposure

- Dust

- Moisture absorption

- Sound measurements

- Power Quality Tests

- Harmonic distortion immunity

- Electrostatic discharge immunity

- Magnetic field immunity

- Capacitor switching transient

Our Proven Experience

Quality Assurance & Technical Standards

- ANSI/ICEA P-45-482

- Short Circuit Performance of Metallic Shields and Sheaths on Insulated Cables

- ASTM F2715

- Standard Specification for Temporary Protective Equipotential Bond Mat To Be Used on De-Energized Equipment

- ASTM F855

- Standard Specifications for Temporary Protective Grounds to Be Used on De-energized Electric Power Lines and Equipment

- BS 6622

- Standards for Construction and Testing of Cables with Thermosetting Insulation

- CSA C2.2

- Pole-mounted, single-phase distribution transformers for electric utilities

- CSA C22.2 No 178.1

- Requirements for Transfer Switches

- CSA C22.2 No 4

- Enclosed and dead-front switches

- CSA C22.2 No. 27-9

- Busways (Tri-national standard, with UL 857 and NMX-J-148-ANCE), Includes Update No. 1 (2011)

- CSA C22.2 No. 280/UL 2594

- Electric vehicle supply equipment (Tri-national standard, with UL 2594 and NMX-J-677-ANCE-2016)

- CSA C22.2 No. 281.1/UL 2231-1

- Standard for safety for personnel protection systems for electric vehicle (EV) supply circuits: General requirements (Tri-national standard, with UL 2231-1 and NMX-J-668/1-ANCE)

- CSA C22.2 No. 281.2/UL 2231-2

- Standard for safety for personnel protection systems for electric vehicle (EV) supply circuits: Particular requirements for protection devices for use in charging systems

- CSA C22.2 No. 282/UL 2251

- Plugs, receptacles, and couplers for electric vehicles (Trinational standard with UL 2251 and NMX-J-678-ANCE-2017)

- CSA C22.2 No.31-18

- Switchgear Assemblies, Includes Administrative Update (2021)

- CSA C22.2 No.4-16

- Enclosed and dead-front switches (Tri-National standard, with NMX-J-162-ANCE-2016 and UL 98), Includes Update No. 1 (2019)

- CSA C61869

- Standards for Instrument Transformers by The Canadian Standards Association

- IEC 60076

- IEC Standard for Power Transformers

- IEC 61230

- Portable equipment for earthing or earthing and short-circuiting

- IEEE 1247

- IEEE Standard for Interrupter Switches for Alternating Current, Rated Above 1000 Volts

- IEEE C37.23

- IEEE Standard for Metal-Enclosed Bus

- IEEE C37.30.1

- IEEE Standard Requirements for AC High-Voltage Air Switches Rated Above 1000 V

- IEEE C57.12.00

- IEEE Standard for General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers

- IEEE C57.12.90

- IEEE Standard Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers

- IEEE C57.13

- IEEE Standard for Instrument Transformers

- IEEE c37.20.1

- IEEE Standard for Metal-Enclosed Low-Voltage (1000 Vac and below, 3200 Vdc and below) Power Circuit Breaker Switchgear

- IEEE c37.20.2

- IEEE Standard for Metal-Clad Switchgear

- UL 98

- Standard For Safety for Enclosed and Dead-Front Switches

- UL 857

- Busways and Associated Fittings

- UL 1008

- Transfer Switch Equipment

- UL 1558

- Standard for Metal-Enclosed Low-Voltage Power Circuit Breaker Switchgear