Overview

Modern society demands that high quality electricity is made available to consumers at all times using transmission and distribution networks comprised of power system components. There are several external factors that accelerate the aging process of power system components including corrosion, fatigue, and overheating. This requires reliable distribution systems and overhead conductors that do not unexpectedly degrade or fail.

Condition testing of overhead conductors helps utilities understand the present condition and health of in-service conductors to aid in prioritizing maintenance or replacement programs.

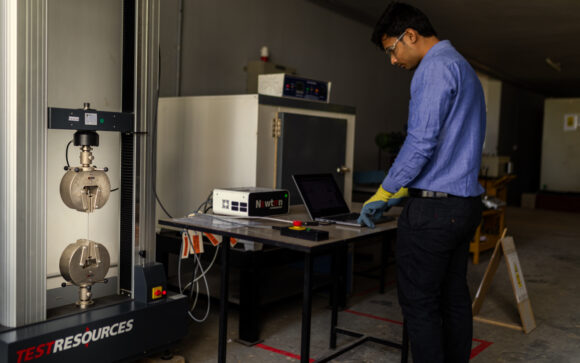

Our conductor testing laboratory is an internationally recognized, third-party, independent facility in Hyderabad, India, that tests High Temperature Low Sag (HTLS) conductors. With a comprehensive set of advanced test machines, we offer a wide range of testing services including ultimate tensile strength, ambient and high temperature stress-strain tests, and coefficient of linear expansion tests.

Why us

-

Independent & Impartial

Testing of HTLS conductors in accordance to industry standards. We are impartial with no affiliation to either the manufacturers or the end users of the equipment being tested.

-

Internationally Renowned Experts

With extensive experience and a deep domain of knowledge, we support testing and provide advice based on the test results gathered to help you make informed decisions about your assets.

-

Project Cost & Time Savings

Our lab is easily accessible from the city of Hyderabad and is a 1.5-hour drive from Rajiv Gandhi International Airport that offers local customers a reliable option to meet fast turn-around time requirements.

-

Trusted Worldwide by Utilities

We type test to multiple global standards including PGCIL, IS/BIS/CEA, IEEE, IEC, BS EN, and ASTM standards, as well as utility specific requirements. Our certification is recognized and accepted worldwide.

-

Overhead Conductor Testing Experience

Having decades of experience, we have become a trusted partner for testing the latest composite wire technologies. We provide accurate measurements and analysis to help you understand the health and life expectancy of conductors.

-

Best-in-Class Quality Management Systems

Global standards and multi-layered Quality Management Systems ensure rigorous and efficient application of sound testing practices. Our integrity and reliability have been built over years of successfully delivering transmission and distribution testing services to our clients.

Technical Abilities

Future Ready

We are capable of testing conductors up to 500 kN ultimate tensile strength and 5000 A rated currents. High-temperature and composite core breaking load tests at 100,000 lbs. capacity can also be performed. Modern amenities and state-of-the-art instruments enable us to offer testing services in accordance with global standards.

Horizontal Test Machine

The hydraulic test machine has a 100,000 lb capacity, at a 15 m sample length, with self-supporting construction. Tests performed by our horizontal test machine includes ambient and high temperature stress-strain/breaking load tests, coefficient of linear expansion tests, and torsional ductility tests.

Conductor Dynamics Spans

Sheave test spans are used to evaluate installation with stresses using simulation at 25,000 lbf and a 35 m sample length. The aeolian vibration test span monitors the impact that wind-induced vibration cycles have on conductors.

Vertical Test Machine

The vertical test machine has a 100,000 lb capacity, at a 3 m sample length, with fully contained equipment. The testing offered with the vertical test machine includes breaking load tests for composite cores, as well as compression and crush tests.

Thermo-Mechanical Test Bay

Temperature cycle and endurance tests can be executed at a 30,000 lb capacity, at a 10 m sample length, with self-supporting construction.

ConductaClean®

ConductaClean® is a reliable, cost-effective system for cleaning the ends of overhead transmission & distribution conductors before compression splicing. ConductaClean® removes oxidation and grime from conductor strands, cleaning conductors to the inner core. By thoroughly cleaning conductor ends with ConductaClean®, you'll achieve superior mechanical and electrical connections, leading to longer-lasting, more reliable electrical infrastructure.

Whether on the ground or in a bucket truck, linemen can complete the job in 6 minutes or less - significantly faster than traditional wire brushing, which can take over 30 minutes per conductor.

ConductaClean® is now available across South Asia exclusively through Kinectrics India. For more details, download our brochure.

ConductaClean® (U.S. patent #8,839,804) incorporates technology developed by EPRI, USA.

Our Proven Experience

Quality Assurance & Technical Standards

- ASTM Standards

- Technical standards by the American Society for Testing and Materials

- BS EN Standards

- British and European Standard Specifications

- IEC Standards

- International standards for all electrical, electronic and related technologies

- IEEE Standards

- Standards developed and maintained by Institute of Electrical and Electronics Engineers

- IS / BIS / CEA Standards

- International Standards / The Bureau of Indian Standards / Central Electricity Authority Standards

- ISO 9001:2015 (2015)

- Quality management systems

- ISO/IEC 17025 (2017)

- General requirements for the competence of testing and calibration laboratories

- PGCIL Specifications