Overview

Medical Personal Protective Equipment (PPE), including face masks, respirators, and gowns, are powerful tools that we can deploy to prevent the spread of viruses and protect healthcare providers and the public from biohazards.

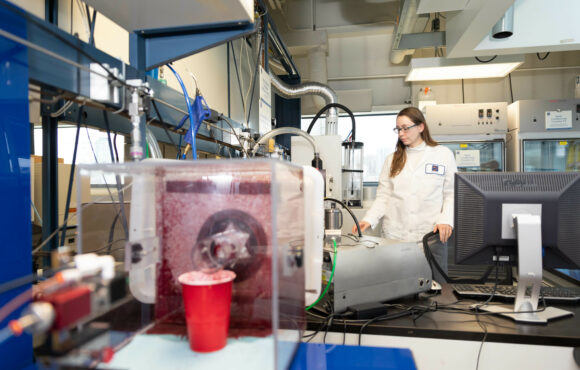

We apply our expertise in aerosol and decontamination research to study the effectiveness of various types of masks, respirators, and gowns to ensure they meet the specific standards for health protection.

We were the first accredited commercial provider of full-scope ASTM F2100 medical face mask testing in Canada aiding in its response to the COVID-19 pandemic.

Why Us?

-

World-Class Facilities and Expertise

Our experienced staff supports the needs of medical PPE testing by using our specialized facilities. This provides assurance of the effectiveness of medical protective equipment following NIOSH, ASTM, and AATCC guidelines.

-

Aging Tests

COVID-19 raised awareness of the importance of testing to confirm the quality and performance of face masks following storage. We conduct ASTM F1980, accelerated aging tests that determine the effects of time on the integrity of medical PPE.

-

Efficient Evaluation of Test Data

All our ASTM F2100 mask testing, NIOSH 95 respirator testing, and PB70 gown testing is carried-out in-house. This allows our team to evaluate and validate test data efficiently

-

Quality Assured

We are ISO/IEC 17025 accredited for ASTM F2100, NIOSH N95 PFE and Breathing Resistance, and ASTM F3502.

Technical Abilities

ASTM F2100 Surgical Mask Testing

In the world of surgical face mask manufacturing, it’s all about standards and producing a compliant product that can offer the maximum amount of protection. Several factors determine the quality of protection provided for ASTM surgical masks including, among other things, the source of the raw materials and how those materials are tested and certified for use in a professional environment. The testing we perform is essential to ensure performance properties are validated to support classification, labeling, and ultimately sales. We offer a full suite ASTM F2100 mask testing (Levels 1 to 3), including bacterial filtration efficiency, resistance to blood penetration, sub-micron particulate filtration, differential pressure, and flammability.

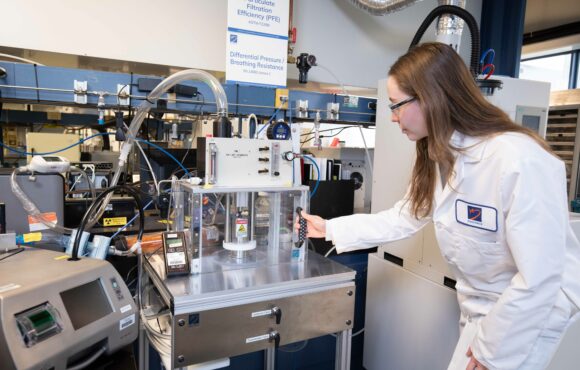

Particulate Filtration Efficiency (PFE)

Particulate filtration efficiency testing evaluates medical masks and materials which provide protection against harmful fumes, dusts, or airborne particulate.

- ASTM F2100/ASTM F2299: This test uses latex particles as a challenge to evaluate filtration efficiency. Level 1 masks must achieve a 95% filtration efficiency with an acceptable quality limit (AQL) of 4%. Level 2 and 3 masks must achieve 98% filtration efficiency with an AQL of 4%

Bacterial Filtration Efficiency (BFE)

Bacterial filtration efficiency testing evaluates medical masks and materials which are intended to provide protection against biological aerosols. These tests use staphylococcus aureus as the bacterial challenge.

- ASTM F2100/ASTM F2101: Level 1 masks must achieve a 95% filtration efficiency with an acceptable quality limit (AQL) of 4%. Level 2 and 3 masks must achieve 98% filtration efficiency with an acceptable quality limit (AQL) of 4%

Resistance to Blood Penetration

Synthetic blood resistance testing evaluates medical masks and materials which are intended to provide protection against blood-borne pathogens.

- ASTM F2100/ASTM F1862: Synthetic blood is directed at a mask at a specified velocity, intended to simulate various human blood pressures. Level 1 masks must achieve an AQL of 4% (29/32) at 80 mm Hg. Level 2 masks must achieve an AQL of 4% (29/32) at 120 mm Hg and Level 3 must achieve an AQL of 4% (29/32) at 160 mm Hg

Differential Pressure

Differential pressure assesses the breathability of a mask or respirator.

- ASTM F2100: Level 1 must achieve < 5.0 mm H2O/cm2 with an AQL of 4%. Levels 2 and 3 must achieve < 6.0 mm H2O/cm2 with an AQL of 4%

Flammability

The flammability of medical PPE is tested to ensure that dangerously flammable textiles are not used in their construction.

- ASTM F2100: Only Class 1, textiles with normal flammability, may be used for medical PPE

NIOSH Respirator Testing

We provide a range of respirator testing services in accordance with 42 CFR Part 84 for medical and industrial and all necessary documentation.

Our testing support includes:

- Sodium chloride aerosol tests to determine the percentage of particulate filtration efficiency

- Inhalation and exhalation resistance testing to measure the breathability of the respirator

- Valve leakage test to measure the amount of leakage between the valve and valve seat

Gown and Drape Testing

We offer gown testing (AAMI PB70 Levels 1 to 3), including water resistance and hydrostatic pressure testing as well as medical drape testing (Level 1 to 4), including water resistance, hydrostatic pressure, and synthetic blood resistance.

Hydrostatic Pressure

Hydrostatic pressure measures the resistance of a fabric to the penetration of water.

- AAMI PB70/AATCC 127: Level 2 gowns must achieve a hydrostatic resistance of > 20 cm. Level 3 gowns must achieve a hydrostatic resistance of > 50 cm

Water Resistance on Impact

Water resistance (impact penetration) predicts the probable resistance of a fabric to spray impact.

- AAMI PB70/AATCC 42: Level 1 gowns must show no more than 4.5 g (of 500 g) of water penetration with an AQL of 4%. Level 2 and 3 gowns must show no more than 1 g (of 500 g) of water penetration, with an AQL of 4%

EN 14683 Surgical Mask Testing

Surgical face masks, when used in a healthcare environment, are primarily used to protect patients from contamination from healthcare providers and vice versa. Because this often involves vulnerable people, it is vital that quality medical face masks are used. We test to the European standard EN 14683 mask testing (Types I, II and IIR), for filtering efficiency of the filter, breathing resistance, microbial cleanliness, and splash resistance.

Accelerated Aging

The COVID-19 pandemic raised awareness of the importance of testing to confirm the quality and performance of face masks following long periods of storage. We are experts at conducting ASTM F1980, accelerated aging testing to determine the effects of time on the integrity of medical PPE.

Our Proven Experience

Quality Assurance & Technical Standards

- 16 CFR Part 1610

- Standard for the Flammability of Clothing Textiles

- AAMI PB70

- Liquid Barrier Performance and Classification of Protective Apparel and Drapes Intended for Use in Health Care Facilities

- ASTM F1862

- Standard Test Method for Resistance of Medical Face Masks to Penetration by Synthetic Blood (Horizontal Projection of Fixed Volume at a Known Velocity)

- ASTM F1980

- Standard Guide for Accelerated Aging of Sterile Barrier Systems for Medical Devices1

- ASTM F2100

- Standard Specification for Performance of Materials in Medical Face Masks

- ASTM F2101

- Standard Test Method for Evaluating the Bacterial Filtration Efficiency (BFE) of Medical Face Mask Materials, Using a Biological Aerosol of Staphylococcus aureus1

- ASTM F2299

- Standard Test Method for Determining the Initial Efficiency of Materials Used in Medical Face Masks to Penetration by Particulates Using Latex Spheres

- EN 14683

- Medical Face Masks Requirements and Test Methods

- ISO 17025 (2017)

- Testing & Calibration Laboratories

Key Clients

Thank you Kinectrics Team, this testing saved the day!