Overview

As transmission and distribution lines age their condition deteriorates and strength is lost creating the potential for catastrophic failure. To effectively manage these key assets, transmission and distribution line operators monitor the condition of their lines. Historically this has involved deenergizing, cutting out a sample for inspection in a laboratory, and repairing using a sleeve. A time-consuming and expensive process.

LineVue® is a family of remotely operated Non-Destructive Inspection tools that measure the remaining cross-sectional area of the steel core wires and identify any local breaks or corrosion pits. LineVue® can be used on both energized (up to 500kv) and de-energized lines avoiding outages and providing instantaneous results without any need for laboratory analysis. Rates of surveying can increase from one a day to 8-12 and entire lengths of line are completely inspected rather than just sampled.

LineVue® has carried-out over 3,600 inspections providing detailed data on over 1 million kms of line.

The system inspects conductors with a steel core (aluminum conductor steel reinforced or aluminum core steel supported) as well as all steel or steel reinforced overhead ground wires.

The LineVue® Family Comprises:

- The Transmission LineVue® Inspection Unit

- The LineVue® Recovery Unit

- Modular LineVue® Inspection Unit

- Distribution LineVue® Inspection Unit

LineVue® products are used in our full LineVue Inspection service or may be leased to users as part of a fully supported package that includes training.

Why Us?

-

No Need to De-Energize

Corona rings allow LineVue® products to be used on live wires up to 500kv, avoiding the need to deenergize prior to inspection.

-

Easily Deployed

LineVue® can be deployed using a bucket truck, ropes/ladders, or a helicopter. The modular unit is deployed by a single operator.

-

Instant Results, No Sampling or Lab Analysis

LineVue® inspects so that sampling, repairing, and analysis are not needed. Instead, data transmission from the tool to the base station provides immediate color-coded details on the remaining steel cross-section and identifies local faults such as pitting or local line breaks.

-

Available as a Service or For Lease

We can undertake the inspection for you, analyze the results and provide advice or we can lease the equipment to you in a fully supported package that includes training. We will work with you to develop the package that most closely suits your needs.

-

Rapid, Error Free, Simple to Read Data

Machine learning is used to remove noise and enable the computer system to select the optimum algorithm for data analysis. Data is presented in simple, easy-to-read, graphics.

-

Inaccessible Regions Made Accessible

The recovery unit allows the transmission unit to be brought back to the installation point enabling easy inspection of spans that are not easily accessible.

Technical Abilities

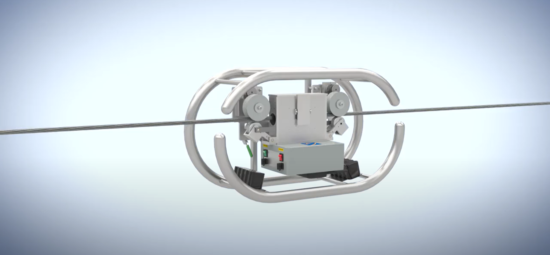

The Transmission LineVue® Inspection Unit

LineVue® inspection devices typically comprise an industrial motor drive, magnets to induce a flux, a free-floating encoder to accurately record distance traveled, a sensing head that takes 5 readings per inch, a real-time data transmitter, data analysis that includes artificial intelligence and machine learning and on-board batteries that can support 4,000 meters of inspection. Local faults are detected using a coil that senses the flux leakage while the loss of metallic area is detected using a Hall Effect sensor. LineVue® technologies can be deployed using a bucket truck, ropes/ladders, or helicopter.

The local fault detector takes readings every 0.2 inches, and the loss of metallic area detector averages the cross-sectional area over 2-3ft with better than +/-5% accuracy.

The original LineVue® technology is optimized for use on transmission lines and is capable of working on lines energized up to 500kv. It is easy to transport and install.

- Dimensions: L=90 cm, W=35 cm, H=53 cm (L=35 in, W=14 in, H=21 in)

- Weight: 31 kg (68lb)

- Conductor Diameter: 15 mm-45 mm (0.59in -1.77 in)

The LineVue® Recovery Unit

The LineVue® Recovery Unit allows utilities to inspect spans that are not easily accessible by bringing the inspection unit back to its place of deployment. The unit can be run in a manual mode with a tethered rope for control or in a fully automatic mode for the safe inspection of energized lines.

It travels along the conductor to the LineVue® inspection unit where a catch mechanism attaches the two units. The recovery unit then pulls the inspection unit back to the installation point for easy access and removal by the line crew.

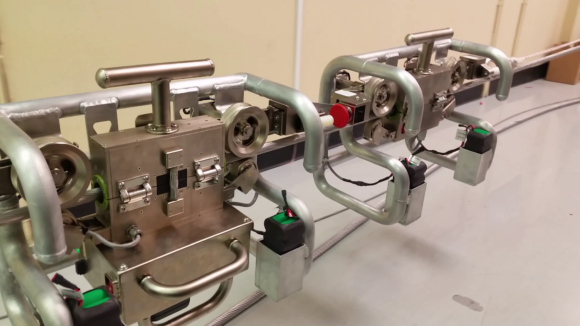

The Modular LineVue® Inspection Unit

The modular LineVue® Inspection Unit carries out inspections on both transmission and distribution size conductors. The unit is made up of a drive, a sensor, and a recovery module.

The unit enables easy lifting and installation by a single line operator and two drive modules maximize sensor use through a leapfrog application. The robust recovery system ensures the LineVue® unit is fully recoverable.

- Dimensions: L=55 cm, W=34 cm, H=46 cm (L=22 in, W=14 in, H=18in)

- Weight: Max 22.6 kg (50 lb.)

- Conductor Diameter: 14 mm-29 mm (0.55 in - 1.14 in)

Distribution LineVue® Inspection Unit

The Distribution LineVue® Inspection Unit offers many new features for inspecting distribution conductors, including reduced dimensions and weight, an accurate sensor head designed for distribution conductors, and an on-board camera for conductor surface inspections.

- Dimensions: L=61 cm, W=38 cm, H=32 cm (L=24 in, W=15 in, H=13 in)

- Weight: 20 kg (45 lb.)

- Conductor Diameter: 6 mm-19 mm (0.24 in-0.75 in)

The Leasing Option

We can undertake the inspection for you, analyze the results and provide advice or we will lease the equipment to you in a fully supported package that includes training so that you can do the work yourself. We will work with you to develop the package that most closely suits your needs.

Leasing is generally the perfect choice if planning to inspect over 150 spans per year. The leasing service includes:

- Training and certifying your staff as LineVue® operators

- Deploying LineVue® and starting inspections based on your preferred schedule

- Off-site and on-site support and/or replacement units if needed

Our Proven Experience

Quality Assurance & Technical Standards

- ISO 9001

- Quality Management System

Key Clients

We have a great experience with LineVue®. It is a very cost-effective tool.